Difference between revisions of "Proposal to Purchase Parts for Dust Collection System"

Dvysotskiy (talk | contribs) |

m (Bot: Cosmetic changes) |

||

| Line 17: | Line 17: | ||

Woodworking dust mitigation has been a longstanding issue at the hackerspace. Various member-driven DIY solutions have been attempted and ended up being either incomplete or unimplemented. In our latest effort to solve this problem, we communicated with a dust collection system manufacturer in hopes for a product donation, however they ultimately declined to help at this time. | Woodworking dust mitigation has been a longstanding issue at the hackerspace. Various member-driven DIY solutions have been attempted and ended up being either incomplete or unimplemented. In our latest effort to solve this problem, we communicated with a dust collection system manufacturer in hopes for a product donation, however they ultimately declined to help at this time. | ||

| − | At this point in our development I see value in spending organization funds to invest in a reasonably priced and capable dust collection system. The system would be completed in a timely manner and integrated into the current plans for the woodworking area. I base my proposal on [http://kregjig.ning.com/photo/2-stage-dc-system this design from Kreg forums] because we already own some of the components to complete it<sup>[1]</sup>, thus recycling what we already have and driving down cost. While the system shall be constructed to be mobile (moving from tool to tool), we have material to attempt a stationary installation for added value. The cost breakdown follows. Note: expenses are overestimated for engineering purposes and efforts to cut costs on the project shall be attempted<sup>[2]</sup>. | + | At this point in our development I see value in spending organization funds to invest in a reasonably priced and capable dust collection system. The system would be completed in a timely manner and integrated into the current plans for the woodworking area. I base my proposal on [http://kregjig.ning.com/photo/2-stage-dc-system this design from Kreg forums] because we already own some of the components to complete it<sup>[1]</sup>, thus recycling what we already have and driving down cost. While the system shall be constructed to be mobile (moving from tool to tool), we have material to attempt a stationary installation for added value. The cost breakdown follows. Note: expenses are overestimated for engineering purposes and efforts to cut costs on the project shall be attempted<sup>[2]</sup>. |

{| class="wikitable" | {| class="wikitable" | ||

| Line 82: | Line 82: | ||

|} | |} | ||

| − | '''Grand total with extra 20%: | + | '''Grand total with extra 20%: $557.74''' |

And there's still the option to save money by reusing things we already have or buying cheaper parts at Home Depot. | And there's still the option to save money by reusing things we already have or buying cheaper parts at Home Depot. | ||

Latest revision as of 23:20, 13 June 2017

| Proposal to Purchase Parts for Dust Collection System | |

|---|---|

| Sponsors | Dmitriy V |

| History | |

| Posted to List | 5/3/2017 |

| Officially Proposed | 5/3/2017 |

| To be voted on | 5/17/17 |

| Results | |

| 6 YES, 3 NO, 1 ABSTAIN - motion PASSES | |

Contents

Language

Allocate $700 from the organization funds for parts to complete a cyclonic separator dust collection system for the woodworking area.

Background

Woodworking dust mitigation has been a longstanding issue at the hackerspace. Various member-driven DIY solutions have been attempted and ended up being either incomplete or unimplemented. In our latest effort to solve this problem, we communicated with a dust collection system manufacturer in hopes for a product donation, however they ultimately declined to help at this time.

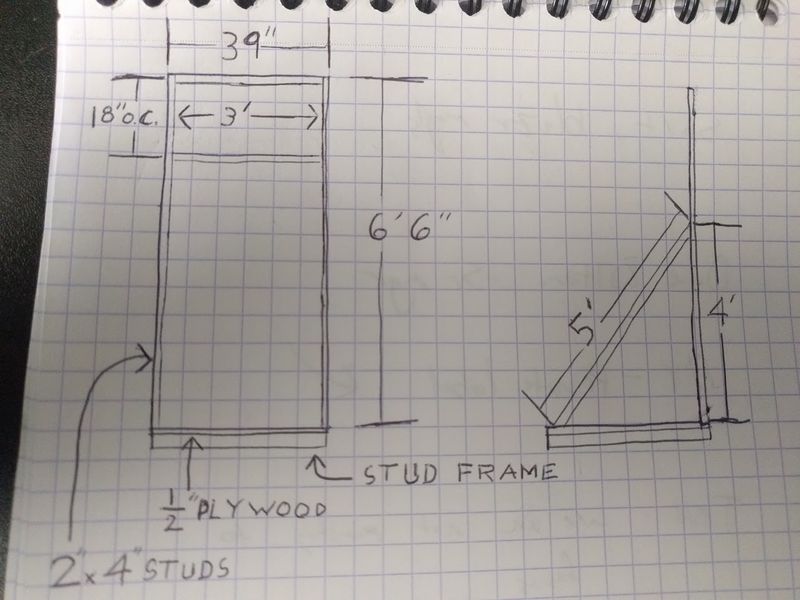

At this point in our development I see value in spending organization funds to invest in a reasonably priced and capable dust collection system. The system would be completed in a timely manner and integrated into the current plans for the woodworking area. I base my proposal on this design from Kreg forums because we already own some of the components to complete it[1], thus recycling what we already have and driving down cost. While the system shall be constructed to be mobile (moving from tool to tool), we have material to attempt a stationary installation for added value. The cost breakdown follows. Note: expenses are overestimated for engineering purposes and efforts to cut costs on the project shall be attempted[2].

| Part | Cost |

|---|---|

| Cyclone | $180 |

| Cyclone Brace | $50 |

| 5" to 4" Reducer | $20 |

| 6" to 4" Reducer | $20 |

| 1.5HP Dust Collector | $350 |

| Lumber, casters, other hardware | $80 |

| Total | $700 |

[1] - Namely a Rubbermaid Brute trash can, trash can lid and possibly dust collector unit.

[2] - Expected cost savings include: purchasing inlet reducers locally from Home Depot - if compatible ($23 savings); replacing cyclone brace with scrap lumber ($50 savings); re-appropriating Harbor Freight dust collector currently used by metalworking members ($350 savings) OR buying same 1HP collector from Harbor Freight (up to $185 savings); using lumber/casters/hardware already available in the space (up to $80 savings).

Costs

Agocs: Here is a breakdown of what this project should actually cost. I'm adding 20% wiggle room to the totals for taxes and any unforeseen costs.

| Part | Cost |

|---|---|

| Cyclone | $179.97 |

| Cyclone Brace | $41.53 |

| 5" to 4" Reducer | $15.39 |

| 6" to 4" Reducer | $16.27 |

| 1 hp dust collector | $149.99 |

| Total | $403.15 |

| Total + 20% wiggle room | 483.78 |

| Required material | Approximate cost | Amount needed? |

|---|---|---|

| Lumber, 2x4x8' | $3.12 ea (menards) | 8 |

| Plywood, 4'x4'x1/2" (to be ripped down to 39" square') | $12.06 ea (menards) | 1 |

| Casters, min 60lb load qty 4 | $16.64 for an 8 pack on Amazon | 1 |

| Screws, Spax, 2.5" construction qty 1 box | $7.97 at the Home Depot | 1 |

| Total | $61.63 | |

| Total + 20% wiggle room | $73.96 |

Grand total with extra 20%: $557.74

And there's still the option to save money by reusing things we already have or buying cheaper parts at Home Depot.